A major step toward the decommissioning of the nuclear power plant, will the investigation robot launch in five years the starting point to change structural problems?

2022 is likely to take a big step for the decommissioning of TEPCO Fukushima Daiichi Nuclear Power Station.For the first unit, a survey robot is invested in the containment container for the first time in about five years.It took three years to launch the aircraft prepared in 2019.This was because it took time to develop an environment where we did not leak radioactive materials.Despite the restrictions on the size, some findings have been established to establish access routes in the container.It is necessary to promote safety measures and modularization of systems and accelerate open innovation.It is noted that it will be a starting point that changes the structural problem of decommissioning technology development.(Takayuki Koji)

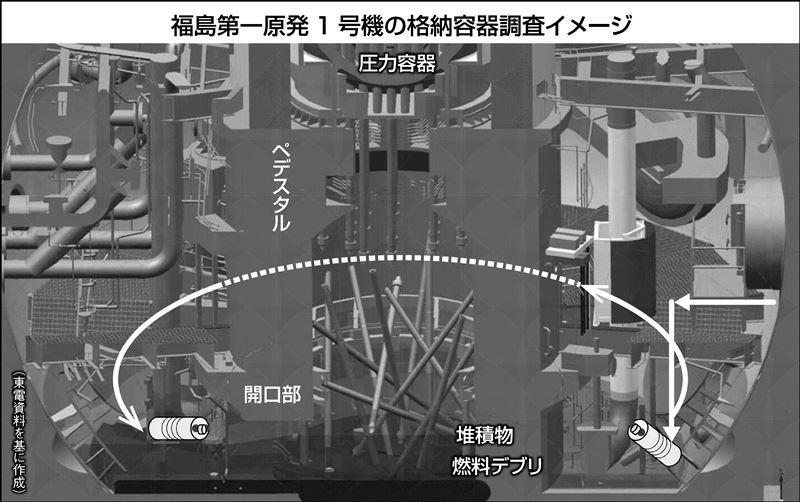

"In the first unit survey, we can get information about what is going on in the containment or sediment.Akira Ono, the representative of the decommissioning promotion company, will focus.In Fukushima Daiichi, an in -house survey begins with the first unit from mid -January.Six underwater water robots (ROVs), a remote -piloted water robot (ROV) from the piping called "X -2 Penn", are sequentially invested in the lower space of the pressure container, which is likely to have melted.This is a survey of the Nagamocho, which is divided into two terms from January to February and May to August.

Unit 1 estimates that debris melted under the pressure container containing the core and spread to the underground floor.I would like to investigate the inside of the structure (pedestal) that supports the pressure container, but the piping on the side of the pedestal opening has a high dose and does not approach.The plan is to put a robot from the X -2 Penna piping on the other side of the opening, turn around the core halfway, and look inside the pedestal.Ono explains, "I think it is difficult to enter the pedestal.Still, it is the first video that captures the inside.We want to identify the required requirements for the debris -out device and reflect it in the subsequent design.

Unit 1 has been examined for the outer periphery of the pedestal.The previous survey in 2017 confirmed that thick sediment was spreading on the outer periphery.The thickness and distribution of this sediment are measured by high output ultrasonic measurement.In advance training, it has been confirmed how the concrete pieces and pipes are filled in the mock sediment and how it is imaged by ultrasonic waves.Although it is difficult to determine damage and shape, it can be considered to check the arrangement of buried items and consider measures.

It will also challenge 3D measurement, nuclope analysis, and sample collection of about 20 cubic centimeters.It is an important step if the identity of the sediment and the distribution of the debris below are divided.

The reason for the start of the investigation from the development of the aircraft to the start of the survey was that it took time to establish safety measures to reduce radioactive dust when cutting structures in the containment container.This is the first time cutting work in the containment container, and it is now possible to directly introduce a large investigation device.

The establishment of this access route will be the foundation for Debris and outloads that will last several decades.Until now, even if university researchers and others tried to bring wisdom and technology, the specifications of the technology required for decommissioning were opaque.The concept is left and the design of specific technology is not proceeded.A researcher in a decommissioned robot, "I only know the detailed technical requirements. I can't start designing and developing robots, so I have to analyze survey data and understand the fusion of core melting (meltdown).I'm pointing out. "

This is a matter of course.TEPCO and heavy industrial manufacturers who build access routes are also designed for seal boxes and other devices in consultation with authorities.There is no established answer yet.Safety is prioritized over open innovation.After repeated surveys and extracts, they will mature safety management and work, and then incorporate external knowledge.

"The difficulty of decommissioning is to manage work safety and improve the environment with a robot," said Kenro Takamori Development Planning Division of the International Decommissioning Research and Development (IRID).In ordinary robot development, it is performed by human hands, such as repairing failures and improving the operating environment.If the machine is broken, the engineer will be fixed and the environment will be improved.However, there is no human in the containment container.If the robot has a problem, the repair will be performed with another robot.

For example, in the debris -out device at the Nuclear Power No. 2, there was a problem that the bolt was broken during the verification work with a double -arm manipulator that replaced the tools of robot arms that take out the work.This bolt is made of stainless steel.Whether there was a problem with the operation or work, whether there was a problem with the design, we are investigating the cause of the break.

Defective measures have become nested for safety measures, such as finding a problem in the robot that takes care of the robot, and the complexity is increasing.Ono explains, "It was difficult to respond if it was found after the launch.The installation of the unit to Unit 2 is aimed at within 22 years.

The work inside the containment container is often unknown, and it is necessary to prepare multiple options.However, it takes time to contain decontamination and containment of radioactive materials, and it takes a yearly time to invest in development technology.During this time, it is costly to maintain the development team, train pilot, and maintain the device.There is also a structural problem that corresponds to machine defects by machine.Ono explains, "It is necessary to consider the Continent Sea Plan (emergency response plan) for the width of the assumption."

The IRID President Toyoaki Yamauchi describes the decommissioning as a difficult challenge comparable to the asteroid spacecraft Hayabusa.In the future, if multiple access routes are established and the method of putting the device in and out of the containment container for each size is standardized, it will be easier to incorporate technologies such as universities and overseas.

22 years will be an important year or one step to take a certain step.

Nikkan Kogyo Shimbun January 1, 2022

Comment

I think Fukushima Daiichi's decommissioning is a more difficult task than going to the month.And there are many problems that should be solved in terms of technology development and development management.If you solve it, it is only a structural problem with impact, so it should be academically valuable.A large amount of technical materials have been published, and if you are a technical management teacher, I think it is a theme that you can bet on your life as a research target.