3D Printing Failures: What You Need to Know to Fix Them

3D printing creates limitless opportunities for invention, but it is not without its challenges. Many users experience disappointing failures that interfere with their creativity, such as warping and nozzle blockages. These difficulties may appear daunting, but knowing the underlying reasons and remedies makes a tremendous difference. Whether you're a beginner or a pro, this guide will explore common problems, practical fixes, and tips for avoiding 3D printing failures altogether. With insights and tools like AnkerMake M5 3D Printer, tackling 3d printing troubleshooting becomes easier and more efficient. Let's dive into solving the issues and achieving perfect prints every time.

Why Do 3D Printing Failures Happen?

Understanding Common Causes of Printing Errors

Mechanical, material and environmental issues can all cause 3D printing problems. Misaligned belts or rods, as well as unstable print beds, might result in shifting layers or poor adhesion. Unsuitable settings, such as printing at an excessively high temperature or at an unsuitable speed, sometimes result in stringing or blobs. Poorly cut files also cause uneven extrusion. The AnkerMake M5, with intelligent calibration and superior slicer compatibility, efficiently addresses these issues. Regular calibration and maintenance, along with proper slicing, are critical for avoiding errors. Whether you are a novice or an expert, recognizing these core problems assures greater print reliability and success.

Materials and Printer Settings That Contribute to Failures

Material selection and printer settings are important for successful 3D printing. Filaments such as PLA, PETG, and TPU require certain nozzle temperatures and cooling settings to provide the best results. Incorrect retraction settings might result in stringing, whilst insufficient bed adhesion causes warping. The AnkerMake M5 makes troubleshooting easier with features like precise temperature control, auto-leveling, and a sophisticated extruder design that ensures consistent filament flow. Adjusting slicer settings such as print speed and fan speed is also required for smooth functioning. Using high-quality filament and tweaking printer parameters reduces errors while improving overall printing performance.

How Environmental Factors Impact Print Quality

Environmental variables such as temperature and humidity have a substantial impact on print quality. Cold surroundings cause the filament to become brittle, but high humidity causes filament moisture absorption, resulting in bubbles or blockages. Stable ambient temperatures and good filament storage are required for reliable outcomes. Tools such as the AnkerMake M5, which has a strong enclosed frame and smart sensors, help to maintain optimal printing conditions. Printing in a temperature-controlled environment and routinely checking filament storage results in smoother extrusion, greater layer adhesion, and fewer failures due to environmental variations.

What Are the Most Common 3D Printing Problems?

Warping and How to Prevent It

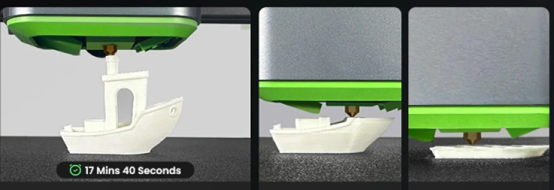

Warping occurs when printed layers cool unevenly, causing parts to curl or lift from the print bed. This often results from poor bed adhesion, inadequate heating, or improper cooling. To reduce warping, use a heated bed with adhesive aids like glue sticks or tape and print with materials like PLA or PETG, which are less prone to shrinkage. The AnkerMake M5, featuring a heated magnetic bed and precise auto-leveling, ensures even temperature distribution and better adhesion, significantly reducing warping risks. Proper material selection and maintaining stable environmental conditions are also essential for preventing this common issue.

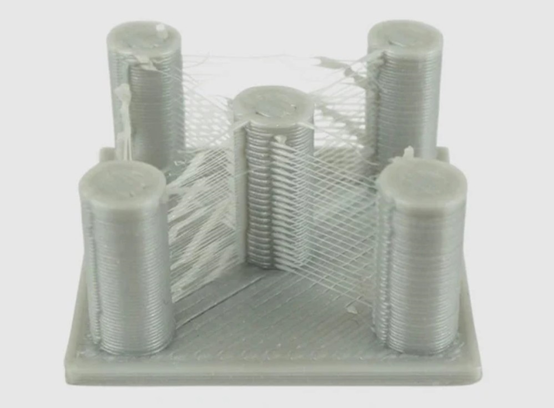

Layer Shifting: Troubleshooting and Fixes

Layer shifting happens when the print head moves out of alignment while printing, resulting in deformed or mismatched layers. Loose belts, motor overheating, and crashes are common causes. To correct layer shifting, tighten belts, reduce print speed, and check the print area for obstacles. Mechanical stability is critical, and the AnkerMake M5's aluminum alloy frame and vibration-damping features reduce movement mistakes. Its superior processing power provides accurate alignment even during high-speed printing. Regularly maintaining printer components and recalibrating settings prevents layer shifting and ensures that prints are uniform and accurate.

Clogged Nozzle: Signs, Causes, and How to Clear It

If the nozzle becomes blocked, the filament cannot flow freely, leading to under-extrusion or failed prints. The accumulation of residue, using the wrong printing temperature, and using contaminated filaments are common reasons. Uneven extrusion or no filament flow at all are symptoms of a blockage. To fix this, just remove the impediments with a cleaning needle or a cold pull. If you clean the nozzle and do not let the filament become wet or dusty on a regular basis, you can avoid clogs in the future. With the AnkerMake M5's built-in error detection system and intelligent cleaning tools, maintaining a clean nozzle is a breeze, resulting in cleaner prints every time.

How Can You Avoid 3D Printing Failures?

Optimize Your 3D Printer Settings

Fine-tuning printer settings is critical for preventing print problems. Proper calibration of bed height, extrusion flow, and retraction reduces difficulties such as stringing and poor adhesion. Testing different slicer settings assures compatibility with a variety of materials. High-speed printers, such as the AnkerMake M5, provide S-smoothing algorithms for smoother surfaces and optimal print paths, which make troubleshooting easier. Furthermore, altering layer height, fan speed, and nozzle temperature increases print dependability. Users may achieve consistent, high-quality outcomes across a wide range of printing projects by calibrating on a regular basis and utilizing powerful slicer tools.

Regular Maintenance to Keep Your Printer in Top Shape

Routine printer maintenance prevents frequent 3D printing issues and increases the life of your equipment. To avoid clogs, clean the nozzle, oil moving parts for better motion, and adjust belts and screws to ensure precision. The AnkerMake M5's error detection system and sturdy aluminum chassis make maintenance easier, lowering the risk of mechanical failure. Regularly inspecting filament pathways and cleaning dust or debris provides uniform extrusion. By creating a maintenance plan, you may save downtime, improve printer performance, and get more consistent results with each print.

Using the Right Materials for Better Results

Choosing the appropriate materials is critical for producing good 3D prints. PLA is easier to use and less prone to warping than ABS, which requires regulated settings to prevent cracking. To avoid clogs or bubbles caused by moisture, keep filaments in airtight containers. The AnkerMake M5, with its precision extrusion and temperature control, can work with a variety of materials, including PLA, PETG, and TPU. Quality materials combined with optimum printer settings ensure smoother prints, greater adhesion, and higher overall quality for your 3D printing projects.

Conclusion

Failures in 3D printing are common, but they are completely solvable with the correct tools and knowledge. Mechanical flaws, material discrepancies, or incorrect settings can all cause problems like warping, layer shifting, and clogging. You can increase print reliability greatly by adjusting printer parameters, doing routine maintenance, and using high-quality materials. Advanced tools, such as the AnkerMake M5 3D Printer, make troubleshooting easier with features like auto-leveling, mistake detection, and rapid printing speeds. With patience and attention to precision, you may overcome obstacles and produce consistent, high-quality prints. Allow innovation to fuel your success in 3D printing.