JDF's buried ear orthodontic appliance, what is the key to reducing the burden on the skin? | New Switch by Nikkan Kogyo Shimbun

JDF (Itabashi-ku, Tokyo, President Muneyoshi Nanai, 03/5914/4311), which assembles prototypes and hanging devices for small radiation devices, has developed an orthodontic device "ear clip" that cures buried ears. Development started at the suggestion of a doctor. After three years of trial and error, we managed to sell it. President Nanai laughs bitterly at the fact that it is not profitable, but he supports the idea that he is benefiting someone.

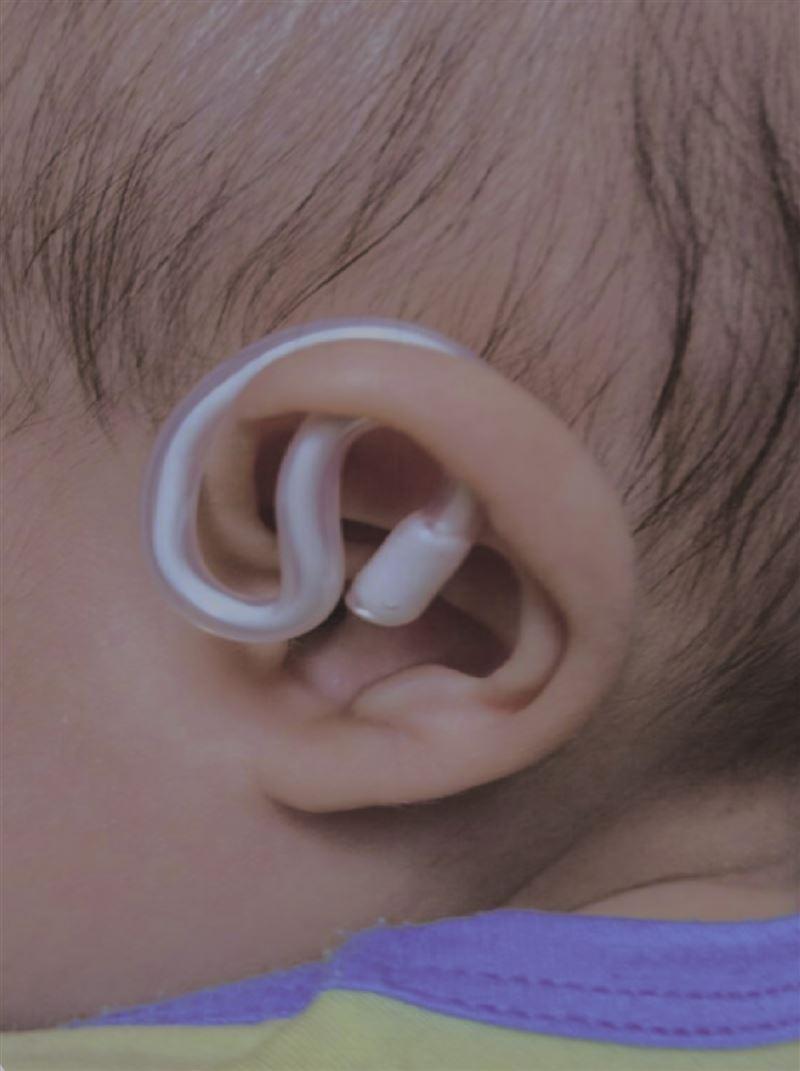

Buried ear is a congenital disease in which the upper part of the ear is buried under the scalp at the base of the ear. It is said to occur in about 1 in 400 people. If left untreated, surgery is required, but it can be treated with orthodontic appliances within about half a year after birth.

The trigger for the development was an exchange meeting for medical-engineering collaboration by Saitama Prefecture Industrial Promotion Corporation. Initially, it was all different from the company's aim, such as "I want something that scratches my back (like my grandson's hand)." Among them, the description about the treatment of buried ears submitted by a doctor at Saitama Children's Medical Center (Chuo-ku, Saitama City) caught my eye and came up with the development.

If the buried ears are left alone, the ears will grow with the ears buried and the mask and earphones cannot be used. Currently, the only cure is surgery or correction. However, general anesthesia is required for surgery, which is a heavy burden on infants. Therefore, doctors often hand-craft orthodontic appliances with paper clips, and it was necessary to devise ways to prevent damage to the skin.

That's why we developed ear clips. It was manufactured by combining a metal wire that was particular about hardness and silicone. Since the correction of buried ears requires regular adjustments, "it was the most difficult to adjust the length, hardness, and material with the doctor," said Toshio Kaneko, director of the development technology department. At that time, the doctors I worked with were so busy that I sometimes waited for a reply for several months.

After repeating trial production and listening to various opinions and advice at exhibitions, etc., in 2018, it started selling to the general public at hospital shops. The size of the product is about 10 cm in length x about 3 mm in thickness. Available in white, pink, and blue. It's all handmade. The price is about 1500 yen (excluding consumption tax) per piece.

The company has a medical device manufacturing license, but does not use ear clips as medical devices. This is because the price will be high if you prepare for risks such as accidents.

For that reason, he decided, "I can't (for medical equipment) when I think of parents who have children with buried ears" (President Nanai). We will keep prices down and prepare for the deficit.

It was a painstakingly developed ear clip, but it was not easy to sell at a hospital shop. This was because it required prior permission from a doctor. Kaneko, director of the development technology department, points out that "medical-engineering collaboration requires building relationships with doctors. It is difficult to connect to business if you are inexperienced." This is because development costs are high and needs cannot be understood without the advice of a doctor. In the case of medical equipment, there is also the risk of free collection / repair (recall).

Currently, he is trying to develop new products, but there are unique difficulties. Even in such a situation, President Nanai shows his pride as a manufacturing company, saying, "I like to propose that I tried to make something like this." (Takumi Shibuya)