Understanding 3D Printer Maintenance

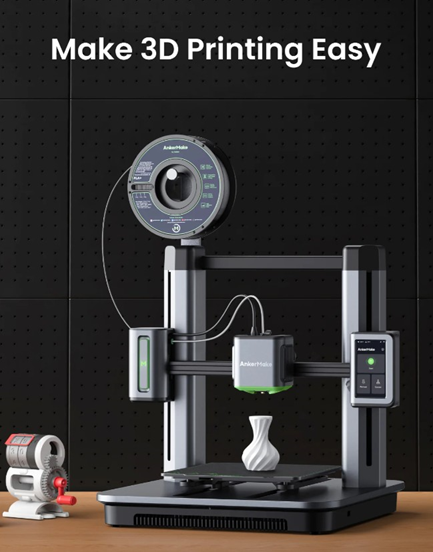

Maintaining a 3D printer maintains its peak performance and durability. Regular upkeep improves print quality, prevents mechanical faults, and lowers costs. Neglecting maintenance causes costly repairs, unsuccessful prints, and a reduced lifespan. Focusing on critical components such as the extruder, print bed, and moving parts helps to ensure consistent output. A systematic maintenance routine improves gadget efficiency, whether for enthusiasts or professionals. AnkerMake makes maintenance easier with user-friendly designs and features like the M5 3D Printer's auto-leveling and real-time monitoring, making it great for anyone looking for dependable, high-quality printing.

Why Is Regular Maintenance Important for Your 3D Printer?

How Maintenance Improves Print Quality

Regular maintenance greatly increases 3D print quality. Cleaning the extruder and nozzle promotes smooth filament flow, and adjusting the print bed improves adhesion and accuracy. These procedures help to avoid typical problems like warping or stringing. AnkerMake's M5 3D Printer, with its 7x7 auto-leveling and strong aluminum chassis, ensures precise and high-speed printing. Consistent upkeep allows for professional-grade output while retaining machine efficiency. By prioritizing routine care, users can produce consistent, high-quality prints, avoiding the frustration and costs associated with failed projects or poor results.

Preventing Mechanical Failures Through Consistent Care

Block nozzles or misaligned belts are common mechanical problems that can arise from ignoring maintenance. These issues disrupt printing and have the potential to damage internal parts. Such breakdowns are avoidable with routine maintenance, which includes cleaning and lubricating moving parts. Take the AnkerMake M5 as an example. Its two Z-axis leadscrew motors, for instance, necessitate routine servicing to guarantee accuracy and durability. Plus, it has an intelligent monitoring system that finds problems quickly, which makes maintenance a breeze. Users may prolong the life of their machines, keep them running smoothly, and save money on repairs by instituting regular care procedures.

Saving Costs With Proper Maintenance Practices

Maintaining a 3D printer lowers long-term expenditures. Cleaning and calibrating components such as the extruder and print bed helps to avoid wear and reduces the need for replacement. The AnkerMake M5 3D Printer's all-metal hot end can handle high-temperature materials, which reduces the need for part upgrades. Regular maintenance reduces wasted filament due to print failures and increases overall efficiency. Users who invest time in maintenance save money on materials and repairs while also assuring smooth, consistent performance. Proper upkeep ensures a cost-effective and dependable 3D printing experience.

What Are the Key Parts to Maintain in a 3D Printer?

Extruder and Nozzle Maintenance Tips

The extruder and nozzle are critical for achieving smooth filament flow and consistent printing. Cleaning with a gentle brush on a regular basis removes clogged and residue. The AnkerMake M5's ultra-direct extruder reduces extrusion errors by minimizing the distance between the filament and the nozzle, hence improving control and reducing blockages. High-quality filament and regular inspections of extruder gears help to reduce wear and ensure reliability. Proper maintenance of these components assures efficient operation, decreases print failures, and increases machine lifespan, making it critical for producing high-quality results.

Cleaning the Print Bed for Optimal Adhesion

If you want your adhesion and initial layer to be perfect, you need a clean print bed. For consistent results, be sure to remove any debris and filament residue after each print. With its PEI soft magnetic steel plate—which is both flexible and scratch-resistant—the AnkerMake M5 is a breeze to clean. Users are able to create prints of professional quality with a reduced risk of print failures, warping, and uneven surfaces, thanks to routine maintenance. Each project may get off to a good start with a clean print bed, cutting down on waste and reprints.

Lubricating and Tightening Moving Components

Moving parts such as belts, bearings, and rails necessitate regular maintenance to ensure smooth functioning. Lubricate the components with machine oil to reduce friction and wear. The AnkerMake M5's aluminum alloy frame dampens vibrations during high-speed printing, but adequate maintenance is required for lifespan. Check and tighten screws and belts on a regular basis to keep them aligned and stable. Consistent maintenance of moving parts eliminates mechanical problems, improves precision, and guarantees that the printer performs well, even during demanding tasks.

How to Create a 3D Printer Maintenance Schedule?

Daily Maintenance Tasks

Daily maintenance tasks include cleaning the print bed and inspecting the extruder for clogs. Remove filament residue to avoid accumulation and guarantee a smooth operation. AnkerMake M5 customers can use the real-time monitoring system to discover faults early on and preserve performance. Simple daily checks limit the chance of unexpected problems and ensure that the printer runs efficiently. These minor but necessary actions serve as the cornerstone of a dependable maintenance routine, delivering consistent outcomes with minimal disturbances.

Weekly and Monthly Checks

Weekly maintenance includes examining belts, bearings, and rails for wear. Lubricate moving parts and tighten screws to maintain stability. Monthly chores include calibrating the print bed and updating the firmware. AnkerMake M5 simplifies these operations with features such as 7x7 auto-leveling and app-based upgrades. Regular inspections prevent mechanical problems, increase efficiency, and extend the printer's life. Establishing a weekly and monthly routine keeps the printer in peak condition, allowing for consistent, high-quality performance.

Annual Tune-ups and Upgrades

Annual maintenance involves a thorough cleaning and potential modifications. Disassemble components to eliminate dust and debris, resulting in smooth functioning. For AnkerMake M5 users, consider replacing damaged nozzles or updating parts like the PEI plate to increase performance. Annual tune-ups address wear and tear that accumulates over time, ensuring the printer's dependability for demanding jobs. A thorough annual review improves efficiency and extends the printer's lifespan, enhancing its value and performance.

Conclusion

Proper maintenance is critical for producing consistent, high-quality 3D printing and extending equipment life. Regular maintenance improves accuracy, reduces mechanical failures, and lowers expenses. AnkerMake's M5 3D Printer includes advanced features such as auto-leveling, real-time monitoring, and error alarms to make maintenance easier. By following a structured maintenance schedule and focusing on key components like the extruder, print bed, and moving parts, users can unlock their printer's full potential. Explore AnkerMake's 3d printers for sale to enjoy reliable performance and hassle-free maintenance, elevating your 3D printing experience to new heights.